Ukuchaneka okuphezulu kwe-CNC ngobhedu

Ukucaciswa kwamalungu omatshini we-CNC ngobhedu

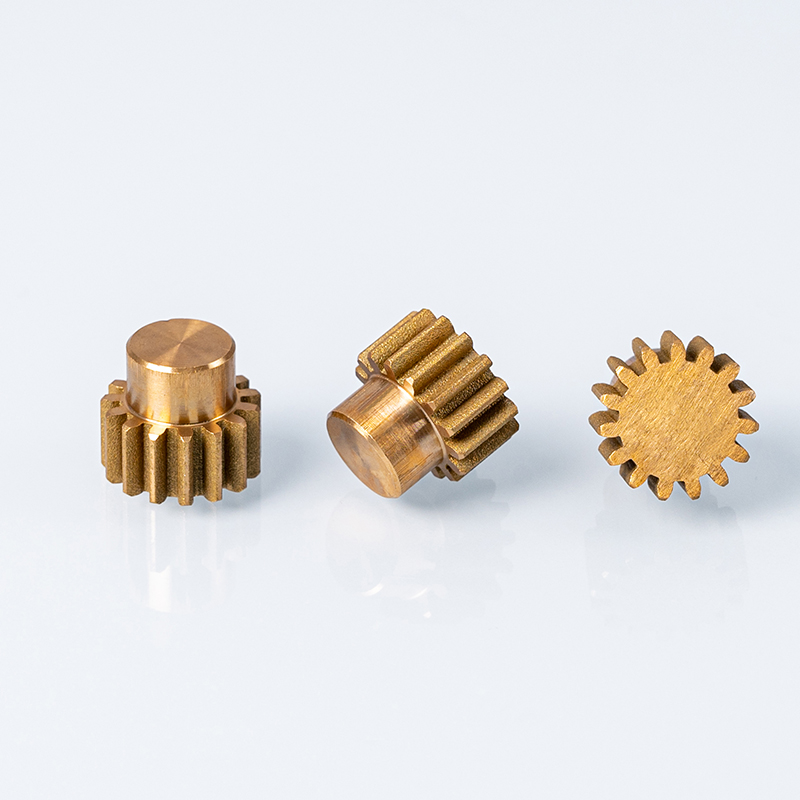

Oomatshini bokwenza i-CNC lubhekisa kwinkqubo yoomatshini beenxalenye zobhedu usebenzisa oomatshini bokuhambisa kwamanani (CNC). Le nkqubo ibandakanya ukusetyenziswa kwezixhobo zokusika, ezinje ngee-drills kunye nee-mills zokuphela, ukwenzela ubhedu kube yimbonakalo efunekayo kunye nobungakanani obufunayo. Inkqubo yomatshini we-CNC ichanekile kakhulu, ivumela iimilo ezintsonkothileyo ukuba zenziwe ngomgangatho ophezulu wokuchaneka.

Olona hlobo luqhelekileyo lobhedu olusetyenziselwe ukoma kwe-CNC yi-C110. Olu hlobo lobhedu lulungele ukubakho kwe-CNC ngenxa yokukhohlisa kakhulu kunye namandla. Enye i-allows yobhedu, efana ne-C145 kunye ne-C175, inokusetyenziselwa umatshini we-CNC ngokuxhomekeke kwisicelo.

Izixhobo zokusika ezisetyenziselwa ukhuphiswano lwe-CNC loshicilelo kufuneka zenziwe ngensimbi yesantya esiphezulu okanye i-carbide. Ezi zixhobo ziyakwazi ukumelana namaqondo obushushu aphezulu aveliswa ngexesha lenkqubo yomatshini. Ukongeza, izixhobo zokusika kufuneka zibukhali kwaye zithathwe ngokufanelekileyo ukuqinisekisa ukuba ngoomatshini abasebenzayo.

Inkqubo yomatshini we-CNC ikwafuna ukusetyenziswa kokuphola ukunceda ekususeni iitshipsi kunye namasuntswana avela kumsebenzi. Ukongeza, umdlali opholileyo unceda ukunciphisa ukwakha kobushushu kwaye axhase ubomi besixhobo esisikiweyo.

Inzuzo yoshicilelo lwe-CNC

Ubhedu oluqhelekileyo lwe-CNC lunika izibonelelo ezininzi, ezinje ngokuchaneka okuphezulu kunye nokuchaneka, ukunqongophala komzimba kunye nokunyuka kombane kunye nokuncipha kombane kunye nokuncitshiswa kwexesha loomatshini ngenxa yophawu lwayo kunye nokuncipha koomatshini.

I-1. Ukomelela kunye nokuqina - ukuqina-ubhedu yinto eqinileyo kwaye iyakwazi ukumelana nobushushu obuphakamileyo, uxinzelelo kunye nokunxiba. Oku kukwenza ukhetho oluhle lokwenza izicelo ze-CNC, njengoko kunokusetyenziswa ngeendlela ezahlukeneyo kwaye kuyakwazi ukumelana neengqongqo eziphindaphindiweyo, ukuchaneka okuphezulu.

2. Ukuqhutywa kweMpumelelo yeyona nto ilungileyo ye-carerr iyenza ilungele ukusetyenziswa kwezicelo ze-CCS ezifuna ukunqunyulwa nokuntywila. Oku kuqinisekisa ukuba imveliso egqityiweyo iya kuba nelona nqanaba liphezulu lokuchaneka nokuchaneka.

3. Ukuqhutywa kombane okuphezulu - Eli nqaku lenza ubhekiso lwezinto ezifanelekileyo zemisebenzi ye-CNC efuna i-wiring yombane okanye izinto.

I-4. I-Copper-isebenza ngexabiso le-Copper ngokubanzi ibizwa kakhulu kunezinye izinyithi, esenza ukuba kuthathelwe ingqalelo ezifezekileyo kwiiprojekthi ze-CNC ezifuna inani elikhulu leenxalenye okanye izinto.

I-5. Kulula ukusebenza kunye--Cover yinto elula yokusebenza nayo, ivumela imveliso ekhawulezayo kunye nokuchaneka okukhulu.

Ubhedu malunga nenxalenye ye-CNC yomatshini

Amalungu oshicilelo e-CNC kubandakanya ukusetyenziswa kwezixhobo ezinqumlayo ezichazayo njengokuphelisa ii-mills zokususa izinto ezivela kumsebenzi wendlela esebenzayo. Inkqubo yokuqhutywa komatshini we-CNC yenziwa ngeSoftware eNtetho yeKhompyuter (i-CAD) kwaye idluliselwe kumatshini nge-G ikhowudi, evumela ukuba iqhubekele phambili intshukumo nganye. Iinxalenye zobhedu zinokuthathwa, zitshintshwe okanye ziguqulwe kuxhomekeka kwisicelo. Ukusetyenziswa ngokwesinyithi kukuqhekeka kwiinkqubo zomatshini ze-CNC, ngakumbi xa ujongene neentsimbi ezinzima njenge-copper efuna i-copper efuna ukuthambisa kobhedu.

Amacandelo oshicilelo e-CNC yoshicilelo yinkqubo yomatshini yokusebenzisa oomatshini abalawulekayo (i-CNC) kwizinto ezibonakalayo. Ubhedu lusetyenziswa kwizicelo ezahlukeneyo ze-CNC kubandakanya ukuthotyelwa, ukubumba, imigca, kunye neenxalenye zokusebenzisa.

Oomatshini bokwenza ubhedu lufuna ukusetyenziswa koomatshini abakhethekileyo boomatshini kunye noomatshini be-CNC oxhotyisiweyo ngezixhobo ezifanelekileyo zokusika ngokuchanekileyo kwaye bebumbe izinto. Inkqubo iqala ngokudala imodeli ye-3D yenxalenye oyifunayo kwinkqubo ye-CAD. Imodeli ye-3D iguqulwe ibe yindlela yesixhobo, eyimithetho yemiyalelo esebenzayo yomatshini we-CNC ukuvelisa ubume obufunayo.

Umatshini we-CNC emva koko ulayishwe ngesixhobo esifanelekileyo, njengokuphela kwee-mills zokuphela kunye nokuntywila iibits, kunye nomxholo emva koko kulayishwa kumatshini. Lo mbandela emva koko uthandwe ngokwesixhobo sendlela yenkqubo kunye nobume obufunayo. Emva kwenkqubo yomatshini igqityiwe, icandelo lihlolwe ukuqinisekisa ukuba liyahlangabezana neenkcazo. Ukuba kukho imfuneko, le nxalenye igqityiwe ngeenkqubo ezahlukeneyo zoomatshini ezifana nokubhabha kunye nokulungisa.

Ngawaphi amalungu omatshini we-CNC anokusebenzisa ubhedu

Iinxalenye ze-CNC zoshicilelo ezinokusetyenziselwa izicelo ezahlukeneyo, kubandakanya izinto ze-elektroniki kunye neenxalenye zeolimotives, i-agurpace ephezulu, izixhobo zonyango, izibonelelo zoomatshini, ezinye iindibano. Amalungu obhedu e-CNC aqhele ukubethwa kunye nezinye izinyithi ukuphucula ukwenziwa okanye ukunciphisa.

Iinxalenye ze-CNC zoshicilelo ezinokusetyenziselwa izicelo ezahlukeneyo, kubandakanya izixhasi zombane, izindlu zemoto, izinto zobushushu, izinto zobushushu, izinto zezakhiwo, kunye nezinto zokuhombisa. Iindawo zobhedu zilungele okwi-CNC ngenxa yombane ophambili kunye nokuqhutywa kombane okuphezulu kunye nokuqhutywa kwe-surrosion, kunye nokunganyangeki kwengqondo. I-CNC yoshicilelo ye-CNC inokusetyenziselwa ukwenza iimilo ezintsonkothileyo kunye neenxalenye ezinamanyala achanekileyo.

Luhlobo luni lonyango oluphezulu olufanelekileyo kumalungu e-CNC Con yobhedu

Olona nyango lufanelekileyo lonyango lwe-CNC yoPheli lwe-CNC loPheli. Ithayi yinkqubo ebandakanya i-electro Ukuphatha nge-slish kunye nokwakha ungqimba lwe-oxide kumphezulu wezinto ezikuyonyusa ukuxhaswa kwempahla kunye nokhuseleko lokucoca. Ingasetyenziselwa ukubonelela ngokugcina okuhoyishini njengemibala eqaqambileyo, iMatte Gqibezela okanye ithoni ekhalayo.

I-Waltveres ye-Copper iphathwa ngokubanzi i-Inckel Plates, i-awvisimeze, kunye nokudluliselwa ukukhusela umphezulu ukusuka kwi-corrosion kunye nokunxiba. Ezi nkqubo zikwasetyenziselwa ukuphucula ubuhle benxalenye.

Isicelo:

Imveliso ye-3C, umhombiso wokukhanya, izixhobo zombane, iinxalenye ze-auto, izixhobo zombane, izixhobo zonyango, izixhobo zokukrakra, ezinye iindawo zokuphola.