Yintoni ukubumba ?

Ukubumba kubhekisa kwinkqubo yokubumba isinyithi (okanye ezinye izinto) ngokuyifudumeza kwiqondo lobushushu eliphezulu kwaye emva koko uyibethele ngesando okanye uyicinezele kwimilo oyifunayo.Inkqubo yokubumba idla ngokusetyenziselwa ukwenza izinto ezomeleleyo nezihlala ixesha elide, njengezixhobo, izixhobo, kunye namalungu omatshini.Isinyithi sifudunyezwa de sibe sithambile kwaye sithambile, kwaye emva koko sibekwe kwi-anvil kwaye sibunjwe ngehamile okanye ucinezele.

Iintlobo Zokuqulunqa

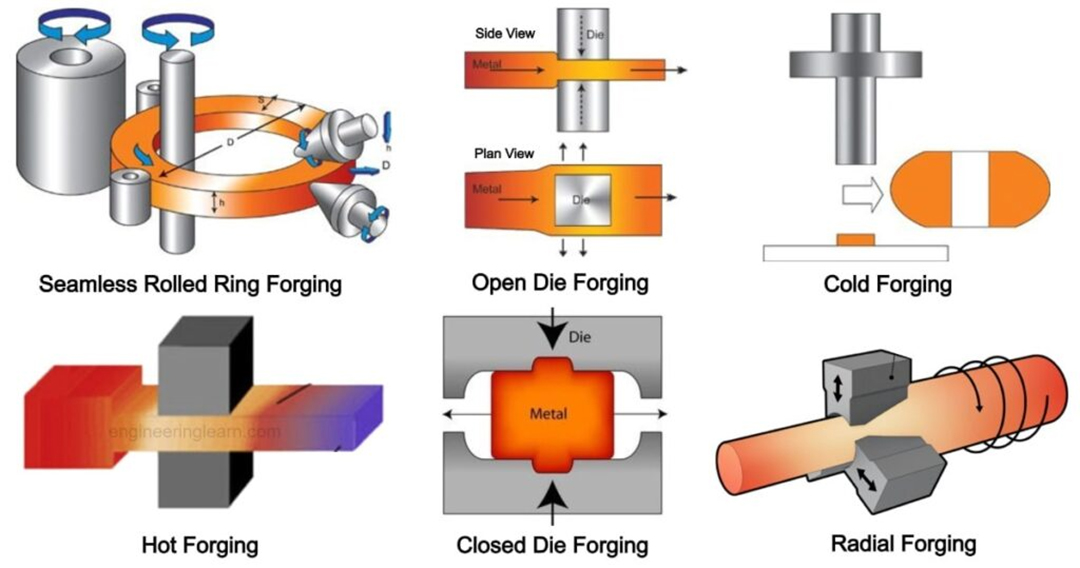

Ukubunjwa yinkqubo yokubumba isinyithi apho izinto zentsimbi zifudunyezwa kwimo yeplastiki kwaye kunyanzeliswe ukunyanzeliswa ukuyikhubaza kwimilo efunekayo.Ngokweendlela ezahlukeneyo zokuhlela, ukubumba kunokwahlulwa ngokweendidi ezahlukeneyo, ezi zilandelayo zezinye iindlela eziqhelekileyo zokuhlela:

- Ngokwemeko yesinyithi ngexesha lokubumba, ukubunjwa kunokwahlulwa ngokwezi ntlobo zilandelayo:

Ukubunjwa okubandayo: Ukubumba okubandayo bubuchule bokusebenza kwesinyithi ukusetyenzwa kwebar yesitokhwe kunye nokuyicudisa kwidayiti evulekileyo.Le ndlela kwenzeka iqondo lobushushu atambient okanye ngaphantsi iqondo lobushushu metal recrystallization ukwenza intsimbi ibe imilo oyifunayo.

Ukutshisa okutshisayo: Ukufudumeza izinto zetsimbi kwiqondo lobushushu elithile ukubenza iplastiki eninzi, kwaye emva koko wenze i-hammering, i-extrusion kunye nezinye izinto.

Ukufudumala okufudumeleyo: Phakathi kokubumba okubandayo kunye nokutshisa okutshisayo, izinto zetsimbi zifudunyezwa kwiqondo lokushisa eliphantsi ukuze kube lula ukwenza iplastiki, kwaye emva koko i-hammered, i-extruded kunye nezinye iinkqubo zenziwa.

- Ngokweenkqubo ezahlukeneyo zokubumba, ukubumba kunokwahlulwa ngokwezi ntlobo zilandelayo:

Ukuqulunqwa kwasimahla: okwakwaziwa ngokuba kukwenza isando sasimahla, yindlela yokubethela kunye nokukhupha isinyithi ngokuwa simahla kwentloko yehamile kumatshini wokwenza.

Die forging: Indlela yokwenza imathiriyeli yentsimbi ngokuyicinezela kwidayizi usebenzisa idiyizi yentsimbi ethile.

Ukubunjwa okuchanekileyo: indlela yokubumba yokuvelisa iindawo ezichanekileyo ezichanekileyo kunye neemfuno eziphezulu.

Ukuqulunqwa kweplastiki: Kubandakanya ukuqengqeleka, ukolula, ukunyathela, umzobo onzulu kunye nezinye iindlela zokwenza, kukwajongwa njengendlela yokubumba.

- Ngokwezixhobo ezahlukeneyo zokubumba, ukubumba kunokwahlulwa ngokwezi ntlobo zilandelayo:

Ukwenziwa ngobhedu: kubhekiselele kwiinkqubo ezahlukeneyo zokwenziwa kobhedu kunye nengxubevange yayo.

I-alloy forging ye-aluminium: ibhekisa kwiinkqubo ezahlukeneyo zokubumba i-aluminiyam kunye ne-alloys yayo.

I-Titanium alloy forging: ibhekisa kwiinkqubo ezahlukeneyo zokubumba i-titanium kunye ne-alloys yayo.

Ukubunjwa kwensimbi engenasici: kubhekiselele kwiinkqubo ezahlukeneyo zokubumba intsimbi engenasici kunye nealloys zayo.

- Ngokweemilo ezahlukeneyo zokubumba, ukubumba kunokwahlulwa ngokwezi ntlobo zilandelayo:

Ukubunjwa kweflethi: Ukucinezela izinto zetsimbi kwimilo ecaba ngokobunzima nobubanzi obuthile.

I-Cone Forging: Ukucofa imathiriyeli yentsimbi ibe yimilo ekhokoyini.

Ukugoba ukubumba: ukwenza intsimbi ibe yimo efunekayo ngokugoba.

Ukwenziwa kweringi: Ukwenza imathiriyeli yentsimbi ibe yimo yeringi.

- Ngokoxinzelelo olwahlukileyo lokubumba, ukubunjwa kunokwahlulwa ngokwezi ntlobo zilandelayo:

Isitampu: Ukusebenza kwesinyithi phantsi koxinzelelo oluphantsi, ngokuqhelekileyo kulungele ukuveliswa kweentsimbi ezincinci.

Medium-pressure forging: Ifuna uxinzelelo olukhulu kunestamping kwaye ihlala ifanelekile ukuvelisa iinxalenye zobukhulu obuphakathi.

I-High Pressure Forging: Ukuqulunqa kufuna uxinzelelo oluninzi kwaye ngokuqhelekileyo kulungele ukuvelisa iindawo ezinzima.

- Ngokwezicelo zokubumba ezahlukeneyo, ukubunjwa kunokwahlulwa ngokwezi ntlobo zilandelayo:

Amalungu e-Auto forging: Yenza iindawo ezahlukeneyo ezifuna ukusetyenziswa ezimotweni, ezinje nge-injini, iindawo ze-chassis, njl.

I-Aerospace forging: iindawo ezifunekayo ukwenza iinqwelo-moya, iirokethi kunye nezinye izixhobo zasemoyeni.

Ukwenziwa kwaMandla: Ukwenziwa kweendawo ezifunekayo kwizixhobo ezahlukeneyo zamandla, ezinje ngeebhoyila, iiinjini zegesi, njl.

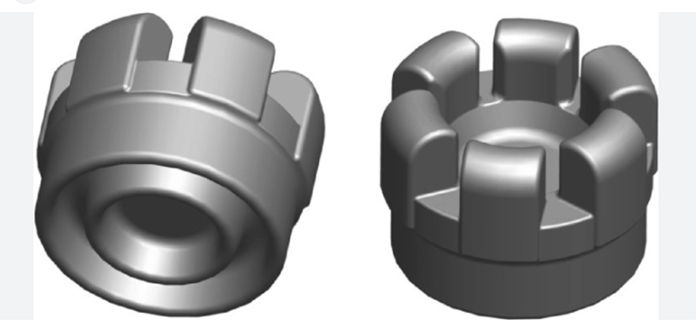

Ukubunjwa komatshini: Ukwenziwa kweendawo ezifuna ukusetyenziswa kwizixhobo ezahlukeneyo zoomatshini, ezinje ngeebheringi, iigiya, iintonga zokudibanisa, njl.

1. Amandla aphuculweyo kunye nokuqina:I-Forging inokuphucula iimpawu ze-mechanic zetsimbi, iyenze ibe yomelele kwaye ihlale iqinile.

2. Ukubumba ngokuchanekileyo:Ukuqulunqa kuvumela ukuchaneka kwesinyithi, okubalulekileyo kwiindawo zokuvelisa ezinemilo ethile kunye nobukhulu.

3. Iimpawu zezinto eziphuculweyo:Inkqubo yokubumba inokuphucula izinto eziphathekayo zetsimbi, ezifana nokuxhathisa i-corrosion kunye nokumelana nokunxiba, okwenza kube yinto efanelekileyo yokufuna izicelo.

4. Inkunkuma eyehlisiwe:Xa kuthelekiswa nezinye iinkqubo zesinyithi, ukubumba kuvelisa inkunkuma encinci kwaye kuvumela ukusetyenziswa kwezinto ezingcono, ezinokunceda ukunciphisa iindleko.

5. Ukugqitywa komphezulu ophuculweyo:Ukuqulunqa kunokubangela ukugqitywa komphezulu ogudileyo, okubalulekileyo kwiindawo ezifuna ukudibana kunye okanye ukutyibilika ngokuchaseneyo.

6. Ukonyuka kwemveliso esebenzayo:Ngokuhambela phambili kwitekhnoloji yokwenza, inkqubo iye yakhawuleza kwaye isebenza kakuhle, ivumela ukwanda kwemveliso.