Iiseramics eziqhelekileyo zeCNC ukuchaneka kweendawo zomatshini

Ukucaciswa kwe-CNC machining ceramics

I-CNC machining yeekeramics yinkqubo yokusika kunye nokubumba izinto ze-ceramic usebenzisa izixhobo zokulawula amanani ekhompyutheni (CNC).Yinkqubo echaneke kakhulu kwaye ichanekile enokusetyenziswa ukuvelisa amacandelo anokunyamezelana okuqinileyo kunye neemilo ezinzima.CNC machining yeeseramikhi zingasetyenziselwa ukwenza amacandelo ahlukeneyo kumashishini, kuquka i-aerospace, ezonyango, kunye neemoto.

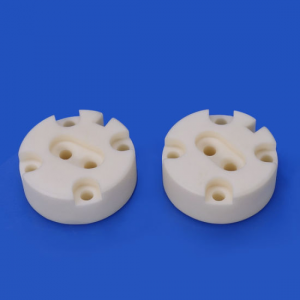

Inkqubo ye-CNC yomatshini iqala ngokukhethwa kwezinto ezifanelekileyo ze-ceramic kwisicelo esijoliswe kuyo.Ngokuxhomekeke kwisicelo, izinto ze-ceramic zinokuvela kwi-alumina, i-zirconia, kunye ne-silicon nitride ukuya kwi-aluminium oxide kunye ne-silicon carbide.Nje ukuba izinto zikhethiwe, imilo efunekayo icwangciswe kumatshini we-CNC.Umatshini we-CNC ke usika ngokuchanekileyo izinto ze-ceramic kwimilo efunekayo.

Emva kokuba i-ceramic isikiwe, iyakhazimliswa ukuba kuyimfuneko.Kumacandelo afuna ukugqitywa komphezulu ogudileyo, i-diamond abrasive isetyenziswa ngokuqhelekileyo.Le nkqubo ikwasetyenziselwa ukuvelisa iinkcukacha ezintsonkothileyo kunye neemilo ezintsonkothileyo.Emva kokuba i-ceramic imathiriyeli ipholisiwe, emva koko ihlolwe ukuqinisekiswa komgangatho.Okokugqibela, amacandelo ke aphantsi konyango olongezelelekileyo olunje ngonyango lobushushu, unyango lomphezulu, kunye neengubo.

Sigxile ekwenziweni kweengxenye ze-aluminium ezichanekileyo ezingezizo ezisemgangathweni ezinezakhiwo ezinzima kwaye sizibophelele ekunikezeni ukuchaneka okuphezulu kunye namacandelo angaguqukiyo kubathengi bethu.Siyaqhubeka kutyalo-mali kwizixhobo ezintsha zomatshini we-CNC kunye nabasebenzi abanezakhono zokuqinisekisa ukuba iqela lethu ligcina inzuzo enamandla yokhuphiswano.Siphinde siphucula inkqubo yokwenza i-aluminium yokuphucula ukusebenza kakuhle kunye nomgangatho, kwaye siqhubeke sihlangabezana neemfuno zemveliso yabathengi.

I-advanteji yeCNC machining ceramics

1. Ukuchaneka okuphezulu: I-CNC yomatshini we-ceramics inokufezekisa ukuchaneka okuphezulu kwe-machining kunye nokuphindaphinda, okunokuhlangabezana neemfuno zecandelo eliyinkimbinkimbi kunye nomatshini onzima womhlaba.

2. Ukusebenza okuphezulu: ngoncedo lwe-CNC machining, ixesha lokucubungula lamacandelo e-ceramic eyinkimbinkimbi lifutshane kakhulu, kwaye ukuveliswa kwemveliso kuphuculwe.

3. Iindleko eziphantsi: I-CNC machining ceramics inokunciphisa kakhulu ixabiso le-ceramic parts processing, kwaye ibe neenzuzo ezilungileyo zoqoqosho.

4. Ukuthembeka okuphezulu: I-CNC machining ceramics inokuqinisekisa ukuchaneka kwe-machining yamacandelo e-ceramic kunye nokuqinisekisa ukuhambelana kweengxenye.

I-5.Umgangatho omhle womphezulu: Umatshini we-CNC unokuphucula ukugqitywa kwendawo ye-ceramic, kwaye wenze iindawo ze-ceramic zibe zihamba kakuhle kwaye zihle.

Indlela iikeramics kwiindawo zokutshiza ze-CNC

I-CNC machining yeeseramics yinkqubo echanekileyo kakhulu efuna izixhobo ezikhethekileyo kunye nezixhobo.Okokuqala, ifayile ye-CAD yenziwe okanye ifayile ye-CAD ekhoyo iguqulelwe ukuchaza inxalenye yejometri.Ifayile ye-CAD ingeniswe kwisilawuli somatshini we-CNC, apho isetyenziselwa ukuvelisa indlela yesixhobo.Umatshini we-CNC usekwa kunye nezixhobo ezifanelekileyo zokusika, ezifana ne-diamond-tipped end mills kunye ne-carbide drills, kwaye inxalenye ilayishwe kumatshini.Ekugqibeleni, umatshini we-CNC usetyenziswa ukusika inxalenye ngokwendlela yesixhobo eyenziweyo.CNC machining yeeseramikhi idla ngokusetyenziswa ukwenza iijiyometri ezintsonkothileyo, ezifana nokufakelwa kwezonyango, amacandelo e-elektroniki, kunye neencakuba ze-iturbine.

Ziziphi iindawo ze-CNC ze-machining ezinokuzisebenzisa kwii-ceramics

CNC machining amacandelo iiseramikhi ngokuqhelekileyo ziquka abasiki, yokusila, iidrili, imizila, iisarha, kunye negrinder.Ezinye izixhobo ezisetyenziselwa umatshini we-CNC weeseramikhi ziquka abasiki be-abrasive, abasiki bedayimani, kunye nezilungisi zedayimani.Ezi zixhobo zisetyenziselwa ukwenza iimilo ezintsonkothileyo kunye nokufezekisa ukugqiba okuchanekileyo kwiindidi ezahlukeneyo zamacandelo e-ceramic.

Luhlobo luni lonyango lomphezulu olufanelekileyo kwi-CNC machining parts of ceramics

Olona nyango luxhaphakileyo kumphezulu lwe-CNC ngoomatshini beseramikhi kukupholisha, ukuqhunyiswa kwesanti, kunye ne-anodizing.Ngokuxhomekeke kwisicelo, ezinye iindlela zonyango ezinje ngokutyabeka, ukupeyinta, kunye nokugquma ngomgubo nazo zingasetyenziswa.

CNC machining iindawo ezingasetyenziselwa CNC machining iiseramikhi ziquka ii-mills ekupheleni, imizila, drills, chamfer yokusila kunye drill bits.