Loluphi uhlobo lwemathiriyeli ekhethekileyo eya kusetyenziswa kwioyile kunye neGesi yeCNC yomatshini?

Izixhobo zoomatshini ze-CNC ezisetyenziswa kwishishini leoli kunye negesi zifuna izinto ezikhethekileyo ezinokumelana noxinzelelo oluphezulu, ubushushu obuphezulu, kunye neendawo ezinobungozi.Nazi ezinye zezinto ezikhethekileyo ezidla ngokusetyenziswa kwioyile kunye nerhasi yomatshini weCNC kunye neekhowudi zazo:

Xa ukhetha imathiriyeli ye-oyile kunye negesi ye-CNC yomatshini, kubalulekile ukuqwalasela iimfuno ezithile zesicelo, ezifana noxinzelelo, ubushushu, kunye nokumelana nomhlwa.Izinto eziphathekayo kufuneka zikhethwe ngokucophelela ukuqinisekisa ukuba inxalenye inokumelana nemithwalo elindelekileyo kunye neemeko zokusingqongileyo kunye nokubonelela ngokusebenza okuthembekileyo kubomi benkonzo obujoliswe kuyo.

| I-oyile eqhelekileyo Material | Ikhowudi yezinto ze-oyile |

| I-Nickel Alloy | Iminyaka eyi-925,INCONEL 718(120,125,150,160 KSI),NITRONIC 50HS,MONEL K500 |

| Yenziwe ngentsimbi eshayinayo | 9CR,13CR,SUPER 13CR,410SSTANN,15-5PH H1025,17-4PH(H900/H1025/H1075/H1150) |

| Isinyithi esingenazibuthe esingenazibuthe | 15-15LC,P530,Idatha yeDathalo 2 |

| Intsimbi yentsimbi | S-7,8620,SAE 5210,4140,4145H MOD,4330V,4340 |

| Ingxubevange yobhedu | AMPC 45,TOUGHMET,BRAS C36000,BRASS C26000,BeCu C17200,C17300 |

| Ingxubevange yeTitanium | I-CP TITANIUM GR.4,Ti-6AI-4V, |

| I-Cobalt-base Alloys | I-STELLITE 6,MP35N |

Loluphi uhlobo lwemathiriyeli ekhethekileyo eya kusetyenziswa kwioyile kunye neGesi yeCNC yomatshini?

Imicu ekhethekileyo esetyenziselwa i-oyile kunye negesi ye-CNC yomatshini kwiindawo kufuneka ziyilwe ukuhlangabezana neemfuno ezithile zesicelo, ezifana noxinzelelo oluphezulu, ubushushu obuphezulu, kunye neemeko zokusingqongileyo ezinzima.Eyona misonto isetyenziswa kakhulu kwishishini leoli negesi ibandakanya:

Hlaziya impendulo

Xa ukhetha intambo ye-oyile kunye negesi ye-CNC yomatshini, kubalulekile ukuqwalasela iimfuno ezithile zesicelo kwaye ukhethe intambo enokumelana nemithwalo elindelekileyo kunye neemeko zokusingqongileyo.Kwakhona kubalulekile ukuqinisekisa ukuba intambo yenziwe kwimigangatho efanelekileyo kunye neenkcukacha zokuqinisekisa ukuhambelana namanye amacandelo kwinkqubo.

Nanku umsonto okhethekileyo wereferensi:

| Uhlobo lwe-oyile yomsonto | Ioyile yoNyango oluKhethekileyo loMphezulu |

| UNRC Umsonto | Vacuum electron umqadi welding |

| Umsonto we-UNRF | Flame sprayed (HOVF) nickel tungsten carbide |

| TC Umsonto | Ukucwenga ubhedu |

| API Thread | I-HVAF (iSibaso soMoya esikwisantya esiphezulu) |

| Spiralock Thread | I-HVOF (Isantya esiphezulu se-Oxy-Fuel) |

| Umsonto wesikwere |

|

| Buttress Thread |

|

| Special Buttress Thread |

|

| Umsonto we-OTIS SLB |

|

| NPT Umsonto |

|

| Rp(PS)Umsonto |

|

| RC(PT)Umsonto |

Loluphi uhlobo lonyango olukhethekileyo lomphezulu oluya kusebenzisa kwioyile kunye neGesi kwiindawo zoomatshini zeCNC?

Ukunyangwa komphezulu wamalungu omatshini we-CNC ngumba obalulekileyo wokuqinisekisa ukusebenza kwawo, ukuqina, kunye nokuphila ixesha elide kwiimeko ezinzima zeshishini leoli kunye negesi.Kukho iintlobo ezininzi zonyango olungaphezulu olusetyenziswa rhoqo kweli shishini, kuquka:

Kubalulekile ukukhetha unyango olufanelekileyo lomhlaba ngokusekelwe kwisicelo esithile kunye neemeko zokusebenza ze-CNC zamacandelo omatshini kwishishini leoli kunye negesi.Oku kuya kuqinisekisa ukuba iinxalenye ziyakwazi ukumelana neemeko ezinzima kwaye zenze umsebenzi wazo ojoliswe kuwo ngokufanelekileyo nangempumelelo.

I-HVAF (I-High-Velocity Air Fuel) &HVOF (I-High-Velocity Oxygen Fuel)

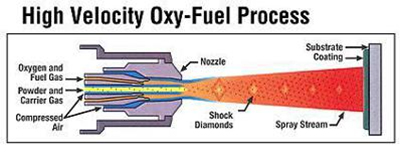

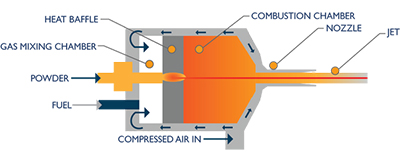

I-HVAF (i-High-Velocity Air Fuel) kunye ne-HVOF (i-High-Velocity Oxygen Fuel) zitekhnoloji ezimbini eziphambili zokugquma umphezulu ezisetyenziswa ngokuqhelekileyo kwishishini leoli negesi.Obu buchule bubandakanya ukufudumeza imathiriyeli engumgubo kunye nokuwukhawulezisa ukuya kwizantya eziphezulu phambi kokuwufaka kumphezulu wenxalenye yomatshini.Isantya esiphezulu se-powder particles sikhokelela kwi-coat eshinyeneyo kwaye ibambelele ngokuqinileyo enika ukuchasana okuphezulu kokunxiba, ukukhukuliseka kunye nokubola.

HVOF

HVAF

Iingubo ze-HVAF kunye ne-HVOF zingasetyenziselwa ukuphucula ukusebenza kunye nobomi beendawo ze-CNC zomatshini kwishishini leoli kunye negesi.Ezinye zezibonelelo ze-HVAF kunye ne-HVOF zokugquma ziquka:

1.Ukuxhathisa ukuMhlwa: I-HVAF kunye nee-HVOF zokugquma zinokubonelela ngokugqwesa ukuxhathisa kwi-corrosion kwiindawo ezinomatshini ezisetyenziswa kwindawo enzima kwishishini leoli kunye negesi.Ezi zogquma zinokukhusela umphezulu wamalungu ekuvezweni kwimichiza eyonakalisayo, amaqondo obushushu aphezulu kunye noxinzelelo oluphezulu.

2.Nxiba ukuxhathisa: Iingubo ze-HVAF kunye ne-HVOF zinokubonelela ngokugqwesileyo kokunxiba kwiindawo ezinomatshini ezisetyenziswa kwishishini leoli kunye negesi.Ezi zogquma zinokukhusela umphezulu weendawo ekunxityweni ngenxa ye-abrasion, impembelelo, kunye nokukhukuliseka.

3.Ukuphuculwa kweLubricity: Iingubo ze-HVAF kunye ne-HVOF zinokuphucula ukuthambisa kwamalungu omatshini asetyenziswa kwishishini leoli kunye negesi.Ezi zambatho zinokunciphisa ukungqubuzana phakathi kweengxenye ezihambayo, ezinokukhokelela ekuphuculeni ukusebenza kakuhle kunye nokunciphisa ukugqoka.

4.Ukumelana ne-Thermal: I-HVAF kunye nee-HVOF zokugquma zinokubonelela ngokugqwesileyo kokuxhathisa kwe-thermal kwiindawo ezisetyenzisiweyo kwishishini leoli kunye negesi.Ezi zambatho zinokukhusela iinxalenye kwi-thermal shock kunye ne-thermal cycling, enokukhokelela ekuqhekekeni kunye nokungaphumeleli.

5.Isishwankathelo, i-HVAF kunye ne-HVOF yokwambathisa ziitekhnoloji zokugquma komhlaba ezikumgangatho ophezulu ezinokubonelela ngokhuseleko oluphezulu kwiindawo zoomatshini ze-CNC ezisetyenziswa kwishishini leoli kunye negesi.Ezi zogquma zinokuphucula ukusebenza, ukuqina, kunye nexesha lokuphila kwamacandelo, okukhokelela ekuphuculeni ukusebenza kakuhle kunye nokunciphisa iindleko zokugcina.