1. Ukumakishwa kweLaser

Ukumakishwa kweLaser yindlela eqhelekileyo yokumakisha ngokusisigxina amacandelo omatshini we-CNC ngokuchaneka okuphezulu kunye nokuchaneka. Inkqubo ibandakanya ukusebenzisa i-laser ukutshiza uphawu olusisigxina kumphezulu wenxalenye.

Inkqubo yokumakisha ngelaser iqala ngokuyila uphawu oluza kubekwa kwindawo kusetyenziswa isoftwe yeCAD. Umatshini we-CNC ke usebenzisa olu yilo ukuqondisa i-laser beam kwindawo echanekileyo kwindawo. Umqa we-laser ke ufudumeza umphezulu wenxalenye, ubangela ukusabela okukhokelela kuphawu olusisigxina.

Ukumakishwa kweLaser yinkqubo engaqhagamshelwanga, oku kuthetha ukuba akukho nxibelelwano lomzimba phakathi kwelaser kunye nenxalenye. Oku kuyenza ilungele ukuphawula iindawo eziethe-ethe okanye eziethe-ethe ngaphandle kokwenza umonakalo. Ukongeza, ukumakishwa kwelaser kunokwenziwa ngokwezifiso kakhulu, kuvumela uluhlu olubanzi lweefonti, ubungakanani, kunye noyilo oluza kusetyenziselwa uphawu.

Izibonelelo zokumakishwa kwelaser kwiindawo zomatshini ze-CNC zibandakanya ukuchaneka okuphezulu kunye nokuchaneka, ukumakisha okusisigxina, kunye nenkqubo yokungaqhagamshelwa enciphisa umonakalo kwiindawo ezibuthathaka. Iqhele ukusetyenziswa kwimizi-mveliso yeemoto, i-aerospace, yezonyango, kunye ne-electronic ukuphawula iinxalenye ngeenombolo zesiriyali, iilogo, iibhakhowudi, kunye nezinye iimpawu zokuzazisa.

Lilonke, ukumakishwa kwelaser yindlela esebenza kakhulu nesebenzayo yokumakisha iindawo zomatshini ze-CNC ngokuchaneka, ukuchaneka, kunye nokusisigxina.

2. CNC Engraving

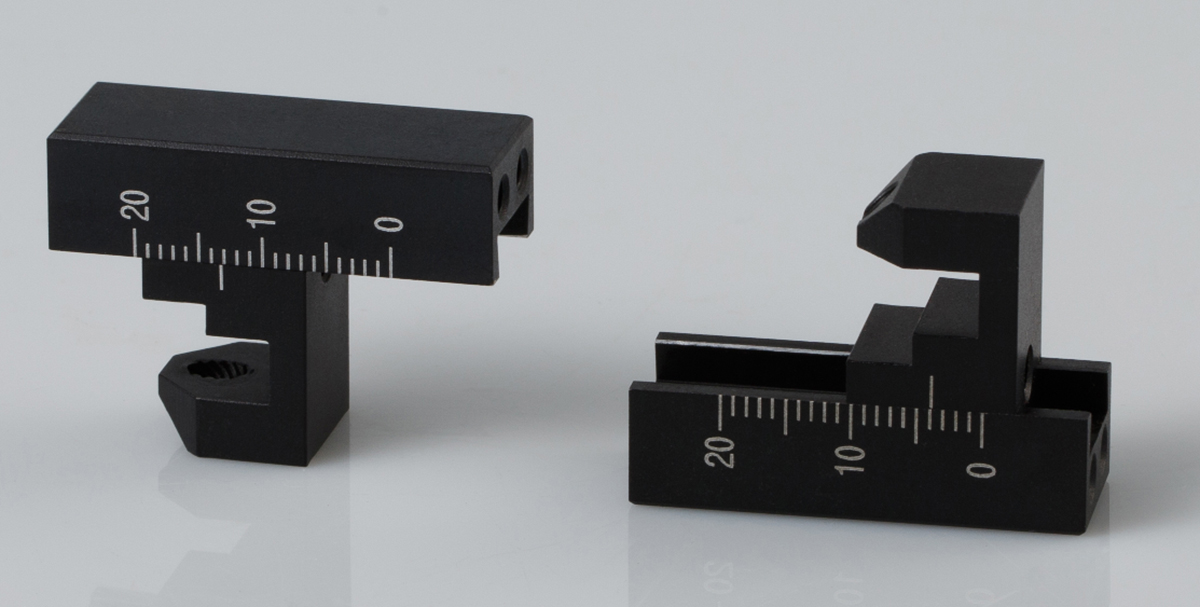

Ukukrola yinkqubo eqhelekileyo esetyenziselwa inxalenye yomatshini we-CNC ukudala isigxina, amanqaku aphezulu achanekileyo kumphezulu wamalungu. Inkqubo ibandakanya ukusebenzisa isixhobo, ngokuqhelekileyo i-carbide bit ejikelezayo okanye isixhobo sedayimane, ukususa izinto ezivela kumphezulu wenxalenye ukwenza umzobo ofunekayo.

Ukukrola kungasetyenziselwa ukwenza uluhlu olubanzi lwamanqaku kumalungu, kubandakanywa umbhalo, iilogo, iinombolo zothotho, kunye neepateni zokuhombisa. Inkqubo inokwenziwa kuluhlu olubanzi lwemathiriyeli, kubandakanywa isinyithi, iiplastiki, iiseramikhi, kunye neecomposites.

Inkqubo yokukrola iqala ngokuyila uphawu olufunekayo usebenzisa isoftware yeCAD. Umatshini we-CNC ucwangciswe ukuba uqondise isixhobo kwindawo echanekileyo kwindawo apho uphawu luya kwenziwa khona. Isixhobo ke sithotywa kumphezulu wenxalenye kwaye sijikelezwe ngesantya esiphezulu ngelixa sisusa izinto zokwenza uphawu.

Ukukrola kunokwenziwa kusetyenziswa ubuchule obahlukeneyo, kubandakanywa ukukrolwa komgca, ukukrolwa kwamachaphaza, kunye nokukrolwa kwe-3D. Ukukrolwa komgca kubandakanya ukwenza umgca oqhubekayo kumphezulu wenxalenye, ngelixa ukukrolwa kwamachaphaza kubandakanya ukudala uthotho lwamachaphaza asondeleleneyo ukwenza uphawu olufunekayo. Ukukrolwa kwe-3D kubandakanya ukusebenzisa isixhobo sokususa izinto kubunzulu obuhlukeneyo ukwenza isiqabu esine-dimensional ezintathu kumphezulu wenxalenye.

Izibonelelo zokukrola kwiindawo zomatshini ze-CNC zibandakanya ukuchaneka okuphezulu kunye nokuchaneka, ukuphawula okusisigxina, kunye nokukwazi ukudala uluhlu olubanzi lwamanqaku kwizinto ezahlukeneyo. Umkroli uqhele ukusetyenziswa kwimizi-mveliso yeemoto, i-aerospace, yezonyango, kunye neye-elektroniki ukwenza amanqaku asisigxina kwiindawo zokuchonga kunye neenjongo zokulandela umkhondo.

Ngokubanzi, ukukrola yinkqubo esebenzayo nechanekileyo enokudala amanqaku akumgangatho ophezulu kwiindawo zokutshiza ze-CNC.

3. Ukumakishwa kwe-EDM

I-EDM (i-Electrical Discharge Machining) yokumakisha yinkqubo esetyenziselwa ukudala amanqaku asisigxina kumacandelo e-CNC. Inkqubo ibandakanya ukusebenzisa umatshini we-EDM ukudala ukukhutshwa kwe-spark elawulwayo phakathi kwe-electrode kunye nomgangatho wecandelo, osusa izinto eziphathekayo kwaye wenze uphawu olufunwayo.

Inkqubo yokumakisha ye-EDM ichaneke kakhulu kwaye inokudala amanqaku ahle kakhulu, acacisiweyo kumphezulu wamacandelo. Ingasetyenziswa kuluhlu olubanzi lwemathiriyeli, kubandakanywa isinyithi, intsimbi, i-aluminiyam, kunye nezinye izinto ezifana neekeramics kunye negraphite.

Inkqubo yokumakisha ye-EDM iqala ngokuyila uphawu olufunwayo usebenzisa isoftware yeCAD. Umatshini we-EDM ke ucwangciswe ukuba uqondise i-electrode kwindawo echanekileyo kwicandelo apho uphawu luya kwenziwa khona. Emva koko i-electrode iyancipha phezu kwendawo, kwaye ukukhutshwa kombane kwenziwa phakathi kwe-electrode kunye necandelo, ukususa izinto kunye nokudala uphawu.

Ukumakishwa kwe-EDM kuneenzuzo ezininzi kwi-CNC machining, kubandakanywa ukukwazi ukudala amanqaku achanekileyo kunye neenkcukacha, ukukwazi ukuphawula izinto ezinzima okanye ezinzima kumatshini, kunye nokukwazi ukudala amanqaku kwiindawo ezigobileyo okanye ezingaqhelekanga. Ukongezelela, inkqubo ayibandakanyi ukudibanisa ngokomzimba kunye necandelo, elinciphisa umngcipheko wokulimala.

Ukumakishwa kwe-EDM ngokuqhelekileyo kusetyenziswe kwi-aerospace, i-automotive, kunye namashishini onyango ukuphawula amacandelo ngamanani okuchongwa, iinombolo ze-serial kunye nolunye ulwazi. Ngokubanzi, ukumakishwa kwe-EDM yindlela esebenzayo kunye nechanekileyo yokudala amanqaku asisigxina kumacandelo e-CNC amatshini.