Yintoni ukuphosa ukufa

I-Die casting yinkqubo yokuvelisa esetyenziselwa ukuvelisa iinxalenye zentsimbi ezinomgangatho ophezulu wokuchaneka kunye nokugqitywa komphezulu. Kubandakanya ukunyanzeliswa kwesinyithi esinyibilikisiweyo kwindawo yokubumba phantsi koxinzelelo oluphezulu. Umngxunya wokungunda wenziwa ziintsimbi ezimbini eziqinileyo ezifayo ezenziwe ngoomatshini ngendlela efunwayo.

Inkqubo iqala ngokunyibilika kwesinyithi, ngokuqhelekileyo i-aluminiyam, i-zinc, okanye i-magnesium, kwiziko. Isinyithi esinyibilikisiweyo sifakwe kwi-mold kuxinzelelo oluphezulu kusetyenziswa i-hydraulic press. Isinyithi siqina ngokukhawuleza ngaphakathi kwesikhunta, kwaye iziqingatha ezibini zokubumba zivulwa ukukhulula inxalenye egqityiweyo.

I-Die casting isetyenziswa ngokubanzi ukuvelisa iinxalenye ezineemilo ezintsonkothileyo kunye neendonga ezibhityileyo, ezinje ngeebhloko zenjini, izindlu zothumelo, kunye nezinto ezahlukeneyo zemoto kunye ne-aerospace. Le nkqubo ikwadume kwimveliso yezinto ezithengwayo, ezifana nezinto zokudlala, izixhobo zasekhitshini, nezinto zombane.

Uxinzelelo Die Casting

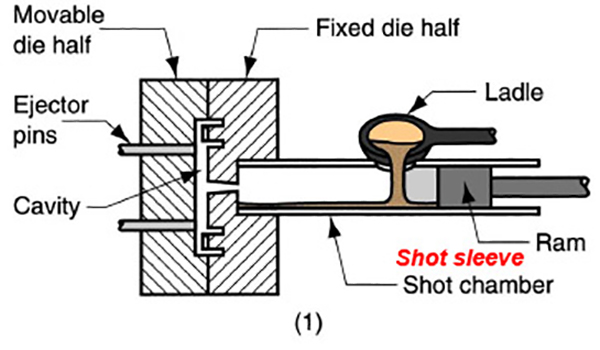

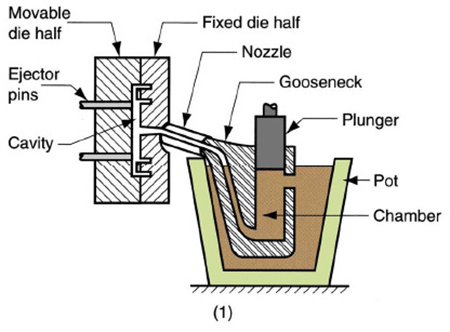

I-Die casting yinkqubo ekhethekileyo eye yaphuhliswa kakhulu kwinkulungwane yama-20. Inkqubo esisiseko ibandakanya: isinyithi esinyibilikisiweyo sigalelwa/sigalelwe kwisingundo sentsimbi kunye nesantya esiphezulu, ngokungaguquguqukiyo kunye noxinzelelo oluqinisayo (kuxinzelelo lokuphosa ukufa) kunye nokupholisa isinyithi esityhidiweyo siyaqina ukwenza ukugatywa okuqinileyo. Ngokuqhelekileyo, inkqubo ngokwayo ithatha imizuzwana embalwa kwaye iyindlela ekhawulezayo yokwenza imveliso yesinyithi kwizinto eziluhlaza. I-Die casting ifanelekile kwizinto ezifana nenkcenkce, ilothe, i-zinc, i-aluminiyamu, i-magnesium ukuya kwii-alloys zobhedu kunye neealloyi ze-iron ezifana nentsimbi engatyiwa. Ezona zinto zisetyenziswayo namhlanje kuxinzelelo lokuphosa ukufa yi-aluminium, i-zinc kunye ne-magnesium. Ukusukela koomatshini bokuqala bokufa abaqhelanisa nezixhobo zokufa ekujongeni ngokuthe nkqo ukuya kumgangatho oqhelekileyo wolungelelwaniso othe tyaba kunye nokusebenza, ukunyanzeliswa kwebha yebhayi emine kunye nenqanaba lenkqubo elawulwa ngokupheleleyo yikhompyuter inkqubo eqhubele phambili kuyo yonke iminyaka.

Umzi-mveliso ukhule waba ngumatshini wokwenziwa kwehlabathi jikelele, wenza amacandelo osetyenziso olwahlukeneyo, uninzi lwawo oluya kuthi lufikeleleke kuwo njengoko usetyenziso lwemveliso yee-die castings zahluka kakhulu.

Izibonelelo zoxinzelelo ziyafa

Ezinye zezibonelelo zoxinzelelo oluphezulu ziyafa:

• Inkqubo ifanelekile kwimveliso yomthamo ophezulu.

• Ukuvelisa iicastings ezintsonkothileyo ngokukhawuleza xa kuthelekiswa nezinye iinkqubo zokwenza isinyithi (umz. ukwenza machining).

• Amalungu anamandla aphezulu aveliswa kwimeko yokuphosa (ngokuxhomekeke kuyilo lwecandelo).

• Ukuphindaphindwa komgangatho.

• Amacandelo amancinane eludongeni anokwenzeka (umz. 1-2.5mm).

• Unyamezelo olulungileyo lomgca (umz. 2mm/m).

• Ukugqiba kakuhle komphezulu (umz. 0.5-3 µm).

Ngenxa yale "ivaliweyo" inkqubo yokunyibilika kwesinyithi / isitofu kunye nentshukumo encinci yomatshini yokuphosa egumbini elishushu lokufa kunokubonelela ngoqoqosho olungcono kwimveliso. Ingxubevange yentsimbi yeZinc isetyenziswa ikakhulu kuxinzelelo lwegumbi elitshisayo lokuphosa inyibilika enendawo yokunyibilika ephantsi ebonelela ngezibonelelo ezongezelelekileyo zokunxiba okuphantsi koomatshini (imbiza, igooseneck, umkhono, iplunger, umlomo wombhobho) kunye nokunxiba okuphantsi kwezixhobo zokufa (ubomi besixhobo obude kakhulu xa kuthelekiswa nezixhobo zokuphosa zokufa kwe-aluminiyam - ngokuxhomekeke kukwamkelwa komgangatho wokuphosa).

Oomatshini begumbi elibandayo bafanelekile kwi-aluminium die casting, iinxalenye kumatshini (umkhono we-shot, i-plunger tip) inokutshintshwa ngokuhamba kwexesha, imikhono inokunyangwa ngesinyithi ukwandisa ukuqina kwayo. I-aluminiyam ialloyi inyibilika kwi-ceramic crucible ngenxa yeqondo eliphezulu lokunyibilika kwe-aluminium kunye nesidingo sokunciphisa umngcipheko we-iron pickup nto leyo engumngcipheko phakathi kwee-ferrous crucibles. Ngenxa yokuba i-aluminiyam iyingxubevange yesinyithi ekhaphukhaphu ngokwentelekiso ivumela ukuphoswa kweecastings ezinkulu kunye ezinzima okanye apho ukomelela okwandisiweyo kunye nokukhanya kwi-die castings kufuneka.